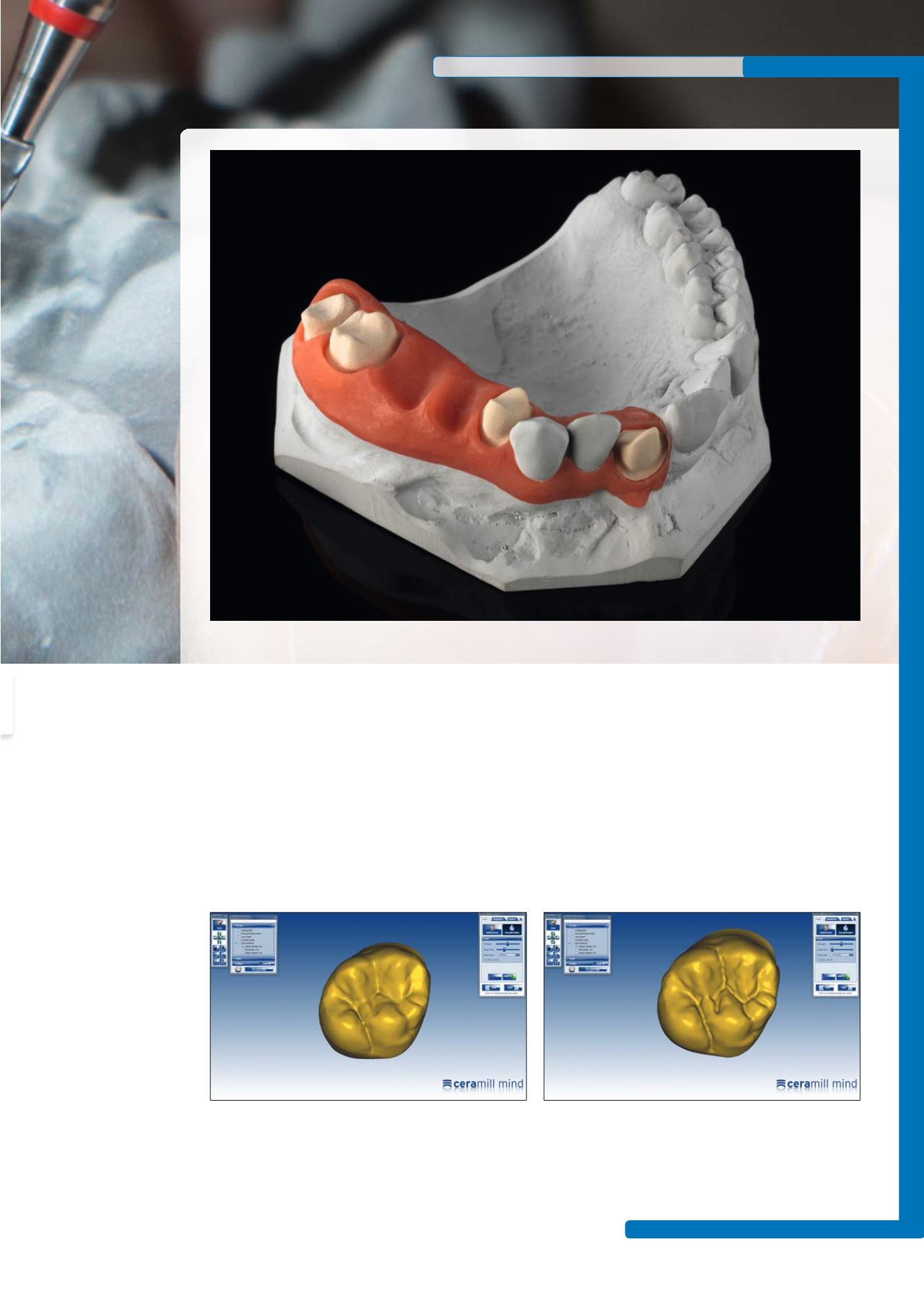

Fig. 1 The demo case: Porcelain veneered single crown on tooth

21 with shoulder preparation, a partially veneered bridge spanning

teeth 24 - 27 as well as a fully anatomical crown on tooth 28 –

all based on Ceramill Sintron.

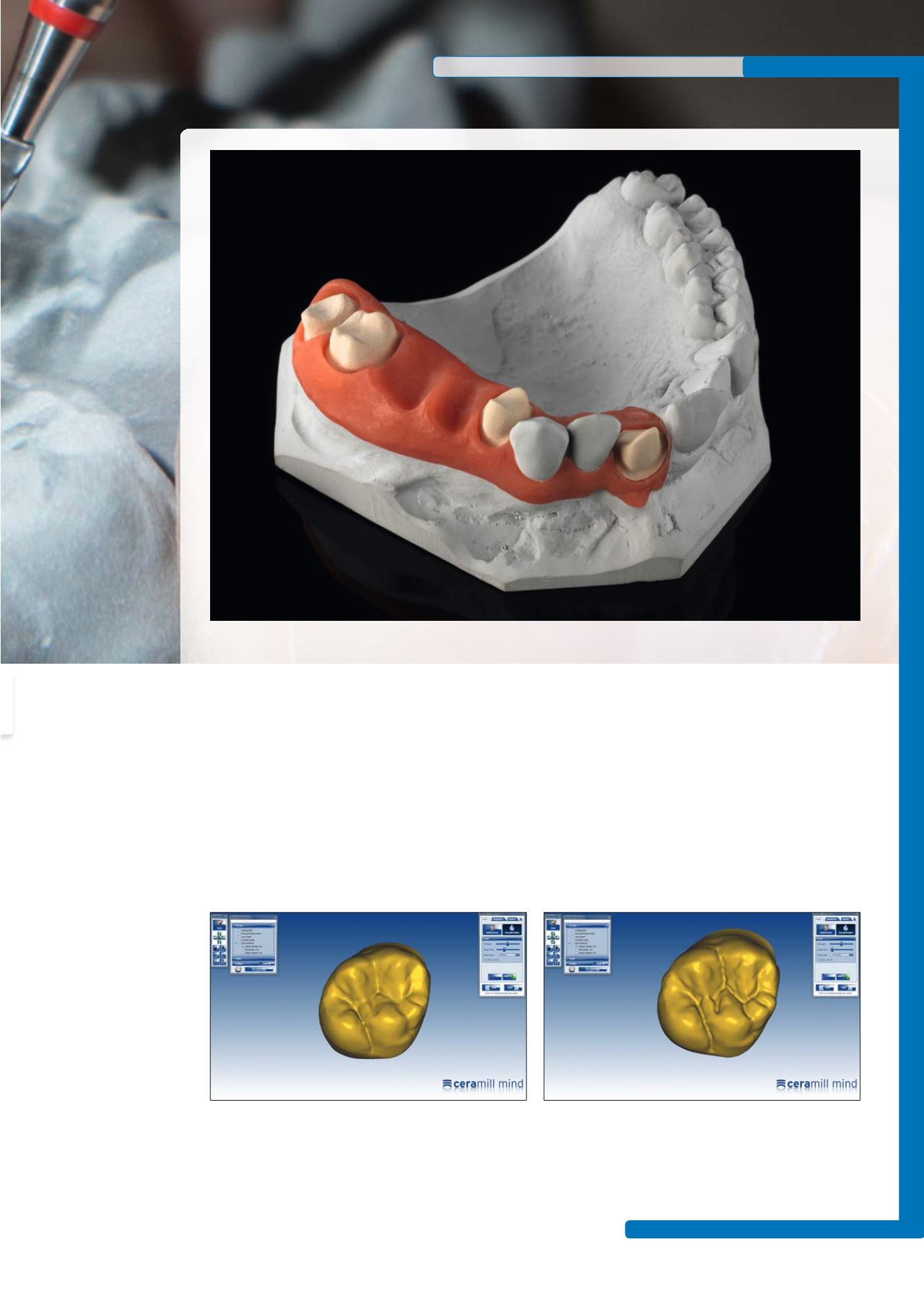

Fig. 2a and b The fissures are opened slightly to larger dimensions to ensure that the designed morphology can also be repro-

duced by the cutters. This appears a little exaggerated but balances out after full sintering.

preparation. These contact parameters

can be easily and precisely defined and

set in the Ceramill Mind CAD software.

After dry milling of the Ceramill Sintron

frameworks in the Ceramill Motion or

Ceramill Motion 2, the restorations are

separated using a conventional, cylindri-

cal tungsten carbide cutter and the con-

nector areas trimmed. Rubber polishers

should not be used, as they could con-

taminate the metal that has not yet been

fully sintered.

The unfired occlusal surfaces can now be

easily and quickly customised and accen-

tuated using conventional instruments

(Fig. 3). Sculpting instruments are also

sometimes used and are excellent for re-

adjusting details. The wax-like consisten-

cy of the unfired framework greatly sim-

plifies this process andmakes the work a

pleasure (Fig. 4a and b).

Care should be taken during manual

preparation to ensure that the minimum

thickness of the framework is not detri-

mentally affected, e.g. by the fissures being

too deep or similar. The material shrinks

by 11 percent during sintering (Fig. 5).

After full sintering, the frameworks are

prepared in the conventional way for the

porcelain veneering and firing process. A

separate instrument set (tungsten carbide

cutter and/or ceramic bonded stones) is

also recommended in this case for prepar-

ing the surfaces to be veneered.

The framework is then sandblasted using

aluminium oxide grit size 110 μm and a

VOLUME 14 06/2013 ©

dent

al

dialog

ue

3

D I G I TAL DENTAL TECHNOLOGY

SPEC I AL

dd

2a

2b