Non-precious metal

comes of age

Chrome cobalt! A term like an impenetrable wall. Hard, cold, merciless. It is little wonder that non-precious

metal dental alloys do not have a good reputation – whether they are called chrome cobalt or non-precious

metal. The association is obvious, as something that is not precious cannot be good. However, non-precious

dental metal alloys are among the most orally resistant, durable dental materials. Amann Girrbach has now

introduced a procedure for processing chrome cobalt without water cooling in a benchtop milling machine.

As the material is in a pre-sintered, wax-like state it can be processed very easily. In this article the excep-

tional dental technician Knut Miller demonstrates how to get the best quality from “chrome-cobalt restora-

tions” with a little skill and knowledge of dental technology.

An article by Knut Miller, Vaduz/Liechtenstein

Knut Miller gives tips on how to produce the best results with Ceramill Sintron

K

nut Miller

is a dental technician

through and through. Someonewho

always wants to go one step further, who

isn’t easily satisfied and strives for perfec-

tion – in particular for natural aesthetics.

This has already been demonstrated in

his cult book “individualitas naturae den-

tis” in which he pays homage to the tooth

shapes and their characteristics. It can be

stated that this man understands his craft

and has integrated the theory of mor-

phology.

Knut Miller

now also works for

AmannGirrbach. At AmannGirrbach he

continually receives a very important

product development fromResearch and

Development to test the performance of

the new material or new technique and

saywhat he thinks has to be changed. One

of these innovations was and is Ceramill

Sintron; a CrCo sinter metal which is

processed while still in a soft state and is

therefore an interesting option for CAD/

CAM in-house fabrication of chrome

cobalt frameworks.

Knut Miller

and non-

precious metal? Yes, this also comes as a

surprise to you initially but after he had

used the material briefly and became fa-

miliar with its remarkable properties, it

became clear to him; chrome cobalt is his

new gold.

Using a demonstration case he describes

in the following article how he fabricates

dental restorations from simple CrCo.

The demonstration case

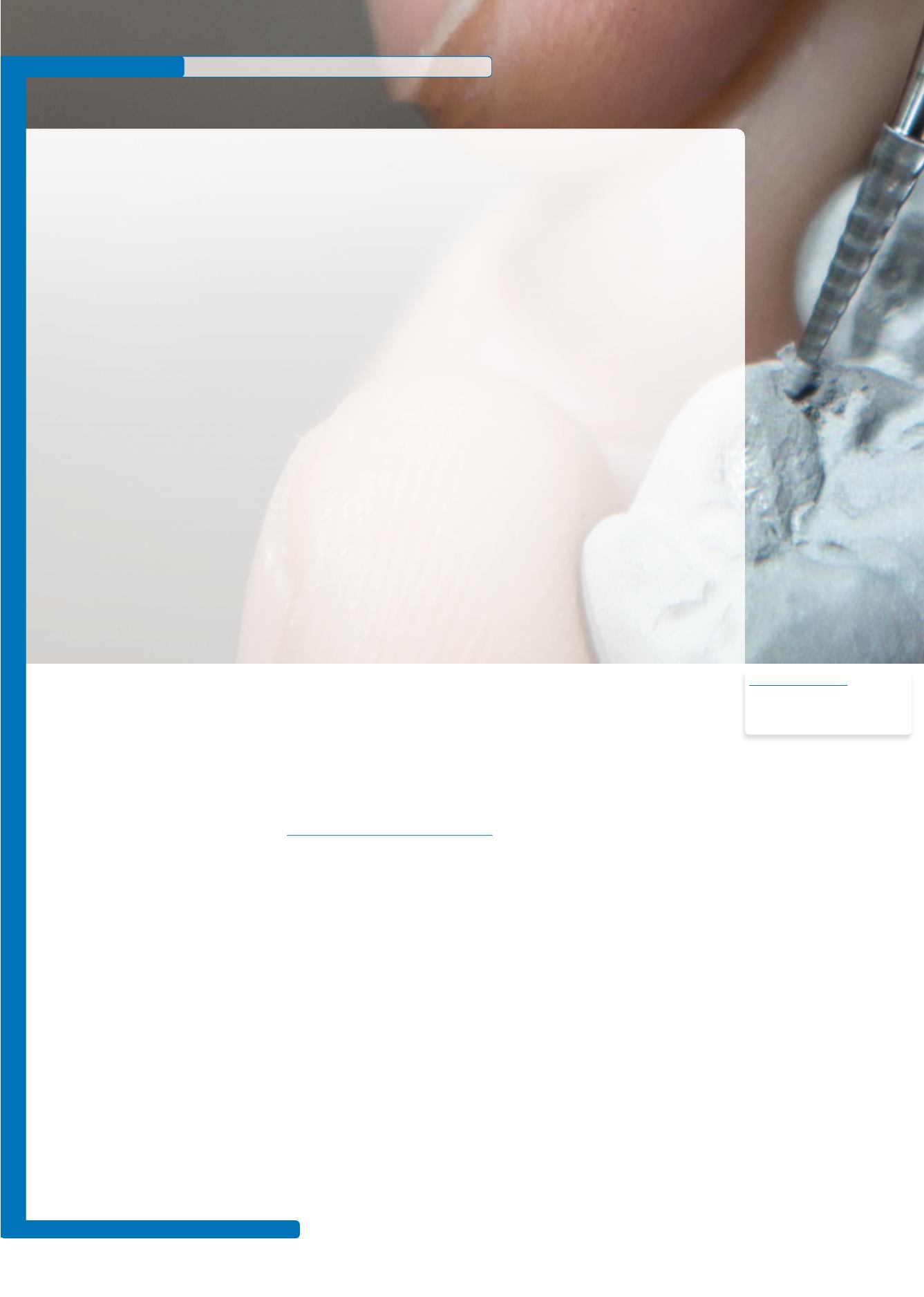

Tooth 21 was to be treated in the demon-

strationwith a fully veneered single porce-

lain crown. A partially veneered bridge

was also to be fabricated from 24 to 27

with the abutment teeth 24 and 27. The

two premolars were to be veneered with

porcelain – tooth 24 with a porcelain

shoulder in the proximal and vestibular

region – and teeth 26 and 27 were to

have a fully anatomical design. A full

crown for tooth 27 was the crowning glo-

ry in the truest sense of the word. A Ce-

ramill Sintron framework with a circum-

ferentially reduced cervical margin was

fabricated for tooth 21 to allow firing on

of a porcelain shoulder (Fig. 1).

The anatomy, morphology and function

can be fully customised and designed us-

ing the Ceramill Mind CAD software.

In this CADworking stage particular at-

tention should be paid to the milling re-

sult of the occlusal surfaces etc. It should

be noted, for example that the 0.6 mm

fine cutter canmill details more efficient-

ly, including the fissures. To ensure this

the fissures in the CAD software should

be opened slightly using the “Knife tip”

modelling tool (Fig. 2a and 2b). Even if

the manipulated details appear to be

slightly “excessively wide”, the fissures can

be more easily defined by the cutter in

this way – which optimises the milling

result.

In addition, when contouring a function-

al occlusal surface of a fully anatomical

restoration it should be noted that the

restorationmust always still be manually

reworked (e.g. polished). The proximal

and occlusal contacts should consequent-

ly be minimally over contoured to pre-

vent the contact points being lost or cre-

ating infraocclusion after mechanical

2

dent

al

dialog

ue

VOLUME 14 06/2013 ©

D I G I TAL DENTAL TECHNOLOGY

dd

SPEC I AL

Category

Product-related

Special article