www.dlonline.de

www.dlonline.de

· dasdental labor · LXII ·

4/2014

31

All or nothing

Function

After merging the designed compo-

nents, the surface is finely finished.

With the end of the “Upper jaw” design

the dental technician now has the finis-

hed restoration on the screen (Fig. 30

to 31). This completes the design.

Data transfer and milling

The operator saves the finished scene

in the Ceramill Mind software. The

technician then opens the nesting soft-

ware to place the framework in the

blank by activating the Ceramill

Match2 CAM software. The software

automatically selects the material de-

termined at the beginning of the data-

base; in this case the translucent zirco-

nium oxide Ceramill Zolid. If there is no

user in the blank library or the correct

height of blank is not available, the

dental technician creates a new one,

which can be used immediately (Fig. 32

to 33).

Using the “Positioning” tool the techni-

cian places the framework in the blank

so that as much material as possible is

saved. It is cost-effective to mill as lar-

ge a number of units from one blank as

possible. The milling path is calculated

after the connectors have been che-

cked and possibly repositioned, (Fig.

34). Once this has been completed, the

operator activates the Motion2 to

transfer the milling data to the machi-

ne (Fig. 35 to 37).

When the spindle and blank holder

have been set to the zero position, the

milling process is started with a final

click on the “Start” button. The type

and size of the framework determine

the duration of the milling procedure.

In this case the dental technician can

assume approx. 45 minutes milling

time (Fig. 38 to 39). Finally, the bridges

are separated from the blank and pre-

pared for the sinter process.

In the next part of this series the au-

thors demonstrate the preparation of

the framework for sintering and also

the fit and function on the model.

n

http://bit.ly/18aYPVI

d

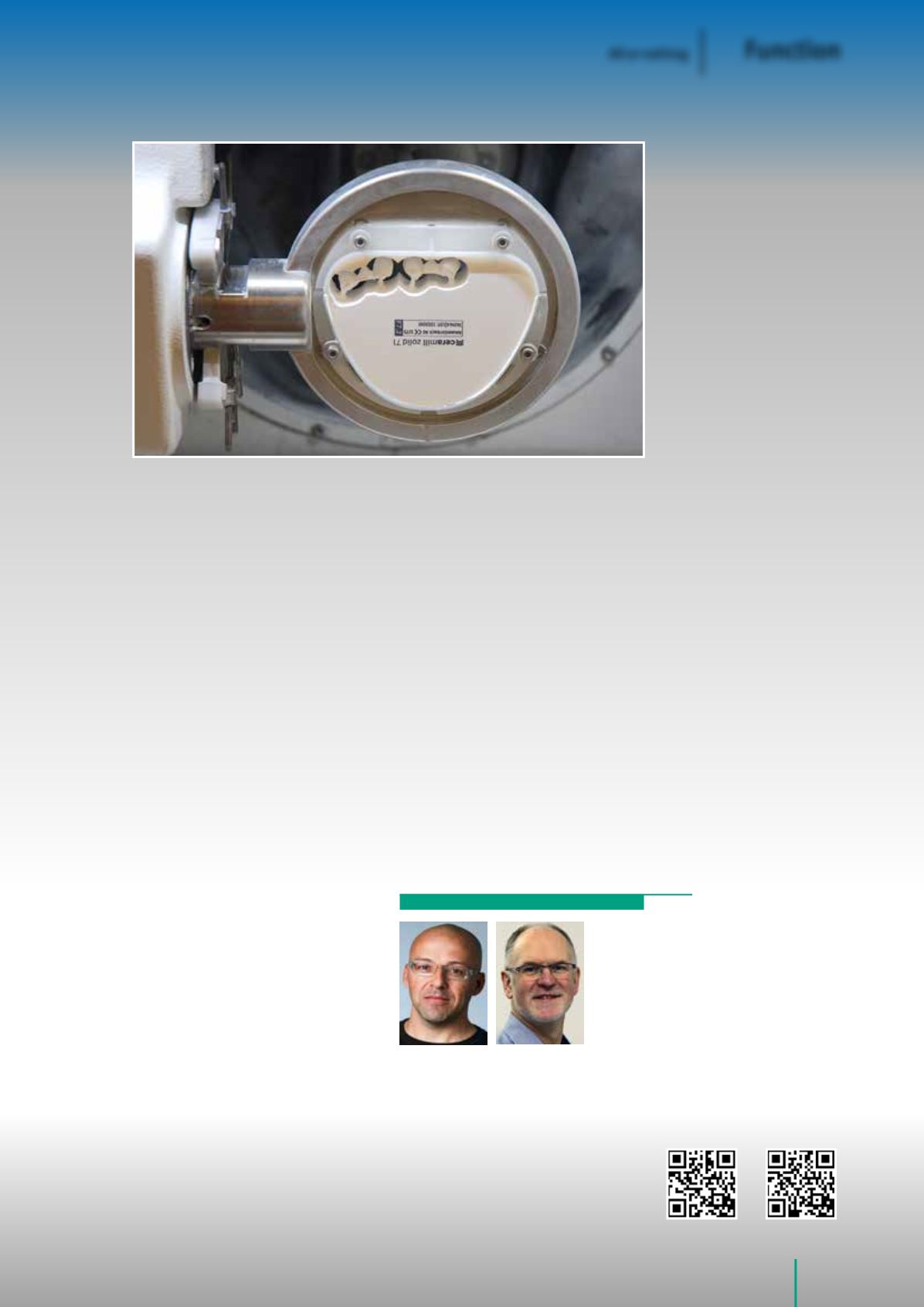

Fig. 39 Milled frameworks

from Ceramill Zolid

Fig. 39

Correspondence address:

Knut Miller, Dietmar Schaan

c/o Amann Girrbach AG

Herrschaftswiesen 1

6842 Koblach/Austria

Internet

www.amanngirrbach.comMore detailed information about

the authors at

www.dlonline.de/ service.de/autoren.htmlhttp://bit.ly/1iBUUFP